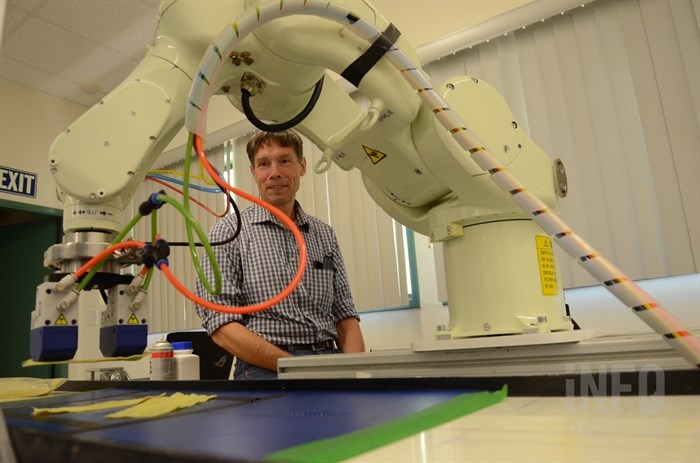

Mike Boudreau stands behind a robot currently being developed to package medical gauze into sterile packets.

(BEN BULMER / iNFOnews.ca)

August 20, 2019 - 6:00 AM

SALMON ARM - A Salmon Arm company is working on the cutting edge of technological design, developing robots with vision and producing technology which 10 years ago simply didn't exist.

But if you're thinking C-3PO, don't. These robots are masters at cheese cutting, sandwich packing and coming soon, mushroom picking.

Salmon Arm's Technology Brewing Corporation has just been awarded $50,000 from B.C.'s Agritech Innovation Challenge for its development of a vision-guided robot capable of accurately picking, trimming and placing mushrooms in store-ready boxes.

"I'm often (asked) aren't you worried about taking people's jobs? Everything that we've automatized people don't want to do," Technology Brewing founder Mike Boudreau said.

Boudreau built his first robot in 1985 and launched Technology Brewing in 1999 transitioning the company into robotics in 2006. As someone on the frontline of the robotic world, Boudreau explains the industry, and it isn't quite what one would expect. The jobs the company's robots have been designed to do are far less glamorous than the robots themselves.

So far the company has developed and sold; a robot now responsible for cutting every block of Kraft cheese in Canada; a robot that puts pre-made sandwiches into packets in the U.K.; and a robot that scores bread sold at Costco and Whitespot, among others.

"We're a small company in the middle of nowhere, relative to where most of our customers are (and) most of the reason why we got to do the interesting things we did us because nobody else was able to do them," Boudreau said. "Most of what we have done... (we) were first."

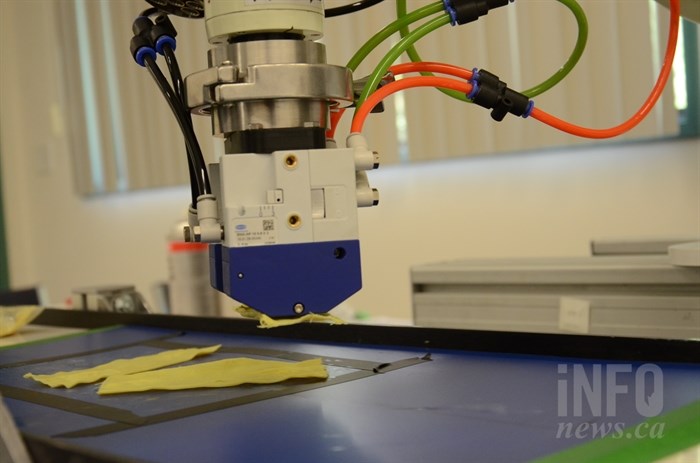

While machines and robots can be programmed to do a certain action to a certain product, any variation in that product and the action will cause problems. Allowing the robot to see the object then allows it to vary its movements when dealing with products that aren't all identical.

The robot that scores bread, slicing a line on top of the loaf as the dough passes from one oven to another, has to be able to see the bread, because every loaf is slightly different.

"The robot has to adapt," he said.

The robot in action.

(BEN BULMER / iNFOnews.ca)

The company is currently developing a robot that can package sterile gauze, a job currently done by hand.

As mushrooms come in different shapes and sizes, and at some stages of their growth double in size in just 24 hours, Boudreau's company is developing a robot that can see the mushrooms, identify which ones to pick and which to leave.

If it sounds complex and expensive it's because it is.

"By the time we've developed a complete system... we'll have spent several million dollars," Boudreau said.

So why mushrooms?

"These are jobs that people don't want to do, that's why there's a demand for the robots in the first place," Boudreau said.

While the Roomba vacuum may be one example of a household robot, (although Boudreau said he bought one and it drove him nuts) having robots do chores around the house still appears to be a long way off.

Boudreau said the sheer expense involved with the technology means industries that can't find labour - like mushroom pickers - will look towards automation, and these are the robots that will be developed.

"It's not just the companies saying we want to reduce labour costs its the companies saying 'Yes, I'd like to reduce labour costs because I can't hire people to reliably show-up and do the job,'" he said.

For the time being these may be the jobs that robots take away from society, but Boudreau believes in the future every job will be affected by automation.

"(With) automated vehicles... you're going to see the job of the long haul trucker disappear, the cab driver disappear," Boudreau said. "You're seeing (artificial intelligence) automate banking, financial transactions... (artificial intelligence) tools supporting health care."

It may sound a long way away, but Boudreau points out, "10 years ago most of what we did, didn't exist."

"I think we've got some societal shifts coming at us and we better think about how we're dealing with that."

The advent of 3D printing has allowed parts, that once needed to be machined off-site, to be produced quickly and inexpensively on-site cutting development time down by as much as two thirds. It's an example of technology which didn't exist a decade ago.

"The bigger picture longer term is all the jobs that we know of today are going to be automated. Yes, they'll be new jobs to build and develop these systems but the definition of work is going to change and how we are compensated is going to change," he said adding: "it's going to be interesting."

To contact a reporter for this story, email Ben Bulmer or call (250) 309-5230 or email the editor. You can also submit photos, videos or news tips to the newsroom and be entered to win a monthly prize draw.

We welcome your comments and opinions on our stories but play nice. We won't censor or delete comments unless they contain off-topic statements or links, unnecessary vulgarity, false facts, spam or obviously fake profiles. If you have any concerns about what you see in comments, email the editor in the link above.

News from © iNFOnews, 2019